Temperature monitoring is essential in industrial environments for ensuring equipment reliability, optimizing operations, and preventing costly failures. Traditional manual inspections are inefficient and often hazardous, making automated monitoring a necessity.

The VoBo solves these problems. In this article, we’ll explore the importance of temperature monitoring and see how the VoBo provides a reliable solution for your monitoring needs.

The Importance of Temperature Monitoring

Effective temperature monitoring plays a crucial role in industrial operations, helping businesses:

- Prevent Equipment Failures – Early fault detection reduces costly downtime and repairs.

- Enhance Safety – Avoid hazardous conditions caused by overheating or extreme cold.

- Optimize Maintenance Planning – Data provides support for predictive maintenance strategies.

- Ensure Regulatory Compliance – Maintain proper environmental conditions for safety and quality standards.

- Improve Energy Efficiency – Optimize machinery efficiency in warehouses and industrial facilities.

- Protect Products – Products and materials require safe temperatures and controlled environments.

Temperature Monitoring with VoBo

There are currently three VoBo models that can either indirectly or directly monitor temperature. Here’s a look at each type of VoBo and our recommendation for your temperature monitoring needs.

VoBo GP-1 and HL-1 – Temperature Monitoring with a Signal Converter

The VoBo GP-1 or HL-1 can read a thermocouple or RTD through common temperature signal converters which output a 4-20mA signal. These VoBos are a good choice if you have other transmitters to connect to the VoBo GP-1/HL-1, or a single temperature transmitter to connect. For multiple temperature sensor applications, the VoBo TC may be a better fit.

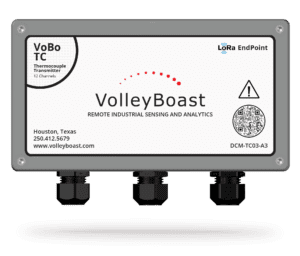

VoBo TC – Multi-Channel Direct Temperature Monitoring

The VoBo TC is the ideal solution for industrial temperature monitoring from multiple measure points. It was designed specifically to read thermocouples. The temperature sensing elements connect directly to the VoBo TC for reliable data collection.

As a rugged, industrial-grade 12-channel thermocouple LoRaWAN® bridge endpoint, the VoBo TC provides a wireless solution for temperature monitoring across many industries, including oil and gas, chemical, manufacturing, mining, cold storage, and more.

The VoBo TC is designed for industrial applications that require reliable temperature measurement using cost effective thermocouples. With 12 individually selectable thermocouple inputs, it can monitor multiple points simultaneously, making it ideal for temperature monitoring in complex environments.

Key Features of VoBo TC

- Supports Type B, E, J, K, N, S, R, and T Thermocouples for broad compatibility.

- Years of battery life for self-contained operation.

- Connects up to 12 thermocouples for large-scale temperature monitoring.

- Each channel can be configured and calibrated independently.

- Class 1 Division 2 Certified in the US and Canada for hazardous areas.

- LoRaWAN® Connectivity enables long-range, low-power, wireless data transmission.

- Up to 6 Miles RF Range (Line of Sight) for extended coverage.

- Cold Joint Compensation ensures measurements are reliable.

- Can be used in offline mode for remote data logging.

With its high-capacity input and LoRaWAN® connectivity, VoBo TC offers a robust solution for industries requiring comprehensive temperature monitoring.

Use Cases in Industrial Temperature Monitoring

There are many use cases for monitoring temperatures with VoBo TC. Here’s a look at just a few examples.

Process Industry: Enhancing Equipment Safety and Reliability

In oil refineries and chemical plants, temperature monitoring can provide valuable insight into their system’s operation. The VoBo TC plays a vital role in monitoring critical assets such as:

- Steam system temperature monitoring

- Motors, compressors, turbines, and heat exchangers

- Pipelines and storage tanks

- Machinery condition monitoring

- Electrical enclosures in hazardous areas

The VoBo TC enables the detection of temperature variances, which allows system optimization, reduces the risk of failures, and improves personnel safety.

Warehouse and Cold Storage Monitoring

Maintaining precise temperature conditions is crucial in warehouses and coolers to prevent spoilage. The VoBo TC helps regulate:

- Ambient temperatures in storage facilities

- Temperature conditions in walk-in coolers and freezers

- Environmental control for sensitive materials and chemicals

By integrating a VoBo TC with thermocouples, businesses can ensure consistent environmental conditions, preventing waste and ensuring quality.

Heat Mapping in Warehouses

Temperature variations in warehouses can result in inefficient climate control and energy waste. VoBo TC helps detect:

- Hotspots and cold zones due to ventilation design

- Hot and cold spots affecting product storage

- Temperature fluctuations impacting material integrity

With better temperature mapping, businesses can optimize HVAC performance and reduce operational costs.

Cold Chain Monitoring for Food and Pharmaceuticals

The food and pharmaceutical industries rely on precise temperature control to maintain product quality. VoBo TC, used with thermocouples and RTDs, helps monitor the temperatures within refrigeration units and freezers, preventing:

- Product spoilage due to cooling failures

- Regulatory non-compliance in food and medical storage

- Wasted inventory caused by undetected temperature fluctuations

By enabling temperature monitoring over LoRaWAN®, a VoBo TC ensures cold storage reliability and product integrity.

Conclusion

Monitoring temperatures is crucial for many industries. The VoBo TC is a powerful and versatile endpoint bridge for industrial temperature monitoring. With its 12-channel thermocouple support, LoRaWAN® connectivity, and hazardous area certification, companies can detect temperature anomalies, optimize processes, reduce maintenance costs, and improve equipment reliability.

For more information, visit the VB TC page or contact info@volleyboast.com.