When deploying LoRaWAN® devices for monitoring and data acquisition, raw sensor measurements aren’t useful until they are converted into a value that has meaning. Operators, analysts, and engineers rely on meaningful, real-world values, such as pressure in PSI, temperature in °C, or tank levels in feet, to make informed decisions. The Volley Boast VoBo makes this easy by providing data in an Engineering Unit representing a physical property, bridging the gap between raw data and actionable insights.

What Is Engineering Unit Reporting?

Engineering Units refer to the standard units of measure used to express physical quantities, such as pressure in PSI (pounds per square inch), temperature in degrees Celsius or Fahrenheit, or force in pounds or Newtons.

Engineering Unit Reporting refers to the ability of a device to process raw sensor data, such as current level, and transmit it in meaningful, human-readable formats. Rather than sending an ADC (analog to digital converter) count, which represents the measured value, the device performs onboard calculations and transmits values that humans can understand, such as:

- 40.95 PSI instead of 1050 ADC counts

- 88.07 °F instead of 1800 ADC counts

- 66.08% full instead of 1450 ADC counts

This simplifies downstream processing and helps ensure consistency. No additional calculations or conversions are required. This enhances efficiency and reduces the effort involved in decoding and utilizing sensor data. This is especially important when using multiple sensors or calculating across multiple deployments.

Why Engineering Units Matter

When the VoBo’s on-board engineering unit conversion is not used, every data stream must implement a unit conversion appropriate for the sensor output range. This increases:

- Development overhead

- Risk of inconsistency

- Dependency on backend configuration

- Risk of errors

The Volley Boast Customer Portal (portal.volleyboast.com) has a tool to generate the formula to convert ADC counts to engineering units, which the user would integrate into the post decoder processing. Doing the engineering unit conversion in the post-processing increases the user’s workload, increases the potential for error, and increases the post-processing compute demand.

Engineering unit reporting is one of VoBos’ greatest time-saving features; the conversions are done on the device, and the value of the physical property is reported in the payload along with its unit of measure. The VoBo sends ready-to-use values, reducing the risk of misinterpretation and simplifying integration with dashboards, SCADA systems, and other customer applications.

Enabling Engineering Unit Reporting with the VoBo

The VoBo supports engineering unit reporting as part of its onboard logic for its 3 analog channels. Each channel is individually configured for the sensor output signal range, its engineering unit range, and unit of measurement. If the sensor has drifted from its true reading, an on-board correction can be applied with a gain and/or offset in the VoBo configuration to correct the value that is transmitted.

VoBo Configuration for Engineering Units

Configuring the VoBo circuit board jumpers for the type of sensor enables the VoBo hardware to read the sensor in a manner compatible with the signal being read. The jumpers on the VoBo circuit board electrically configure each channel. The user manual has detailed information on how to configure the jumpers and connect the sensor.

The VoBo firmware parameters can be configured with a local connection to a computer using a terminal application, the VoBoConfig Tool GUI, or remotely with downlinks. You can select whether it reports the analog channel values in ADC counts or Engineering Units. When Engineering Units is enabled, the transformation for each connected channel must be configured.

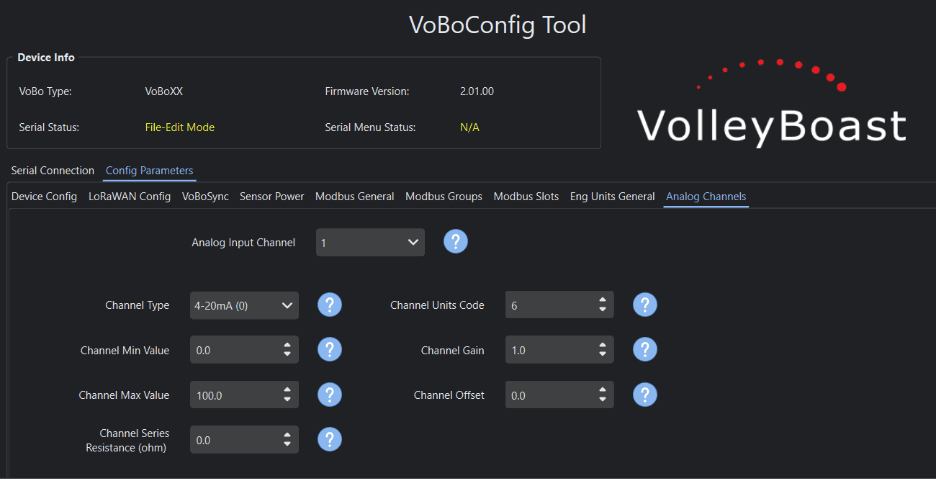

For example, Channel 1 has a pressure transmitter connected with a 4mA to 20mA loop-powered output, calibrated for a 0 to 100 psi pressure range. The jumpers are set to a 4-20mA loop-powered configuration.

The parameter configuration for the engineering unit’s conversion using the VoBoConfig Tool is shown below.

This configuration sets the linear transformation of the measured current between the endpoints 4mA=0psi and 20mA=100psi. The Channel Units Code of 6 instructs the payload decoder to report “psi” as the engineering unit for the channel. A table of engineering unit codes and their unit description is in the user manual. The settings for Channel Gain=1 and Channel Offset=0 do not apply any output signal calibration.

For transmitters that have an output signal that does not align with the measuring range of the VoBo’s analog input channel options (4-20mA, 0-5V, 0-10V), an additional calculation is required, with the stipulation that the sensor’s output signal range is within the measurement range of the VoBo.

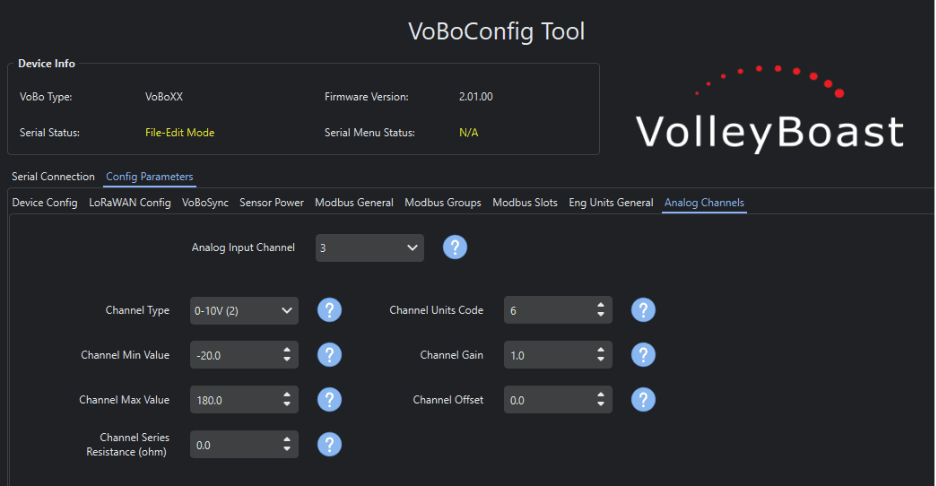

For example, Channel 3 has a pressure transmitter connected with a 1V to 6V voltage output signal, calibrated for a 1V=0psi to 6V=100psi pressure range. Since the 1-6V output does not align with the 0-5V or 0-10V measurement ranges of the VoBo, the 0-10V range is selected because it encompasses the 1-6V output signal range of the pressure transmitter. The VoBo circuit board jumpers are set to the 0-10V configuration.

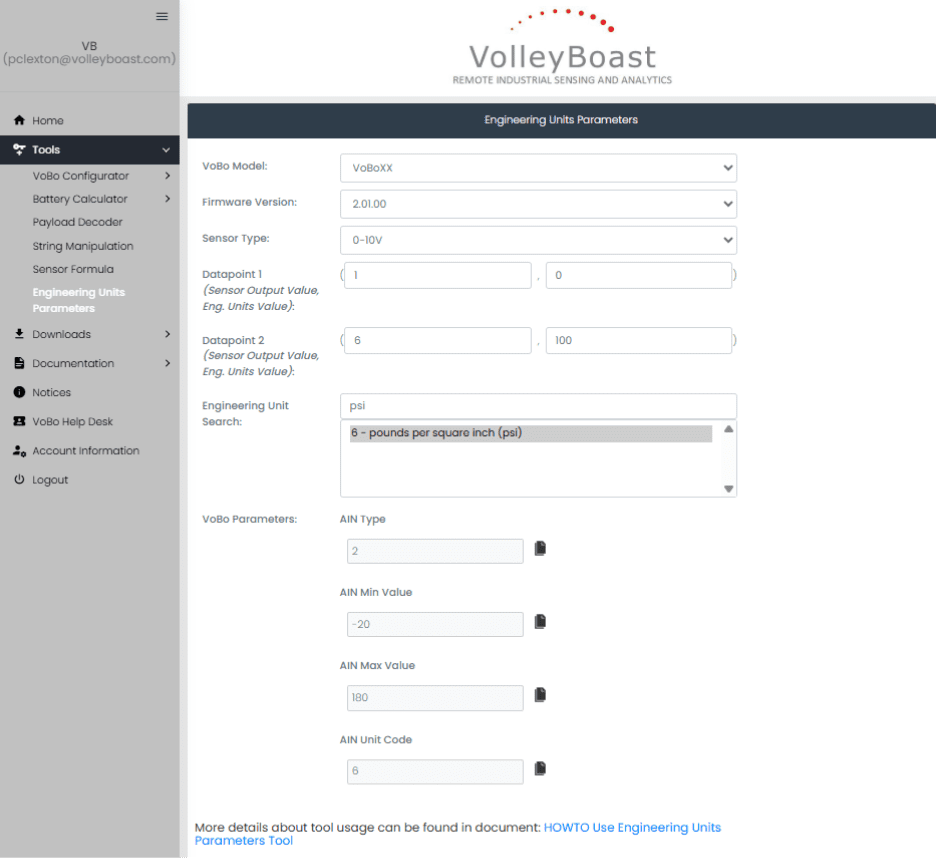

The VoBo 0-10V measure circuit parameter endpoints for engineering unit calculation are adjusted so the VoBo outputs the correct engineering unit value over the 1-6V sensor output range. The Engineering Units Parameters section in the Volley Boast Customer Portal can do the calculation for you.

Enter the VoBo sensor type and the sensor output datapoints with their corresponding engineering unit values. The tool shown below calculates the VoBo parameters to enter into the configuration, which will allow the VoBo to properly translate the sensor output into an engineering unit value in this example.

The calculated VoBo parameters from the portal tool above are configured on the VoBo as shown in the VoBoConfig Tool below.

Streamlined Data Acquisition and Analysis

By delivering sensor data in Engineering Units, VoBo eliminates the need for further calculations or post-processing to convert the payload data into meaningful engineering values. Engineering units’ payloads use a different payload structure specifically designed to deliver the channel number, its measured value, and the units in the payload.

This significantly simplifies data acquisition and enables faster deployment and data that is ready to use.

Benefits for Industrial and Remote Applications

Using engineering units in your VoBo deployments helps:

- Streamline integration with the data historian, analytics, and data visualization

- Eliminate the possibility of errors or inconsistency in the transformation

- Simplifies troubleshooting with units that are easily understood

When to Use Engineering Unit Reporting

We recommend that you always enable Engineering Units with VoBo if possible. They simplify data analysis by providing the channel, value, and corresponding units within the payload itself, eliminating the need for post-processing, so the data is always ready to use.

When Not to Use Engineering Unit Reporting

There are times when you may choose not to enable engineering units.

For example, if you have existing VoBos already deployed for an application with the post-processing and workflow in place, you may want to continue on that path. In this case, changing to engineering units could be disruptive to your process.

You may choose to disable engineering units when there are concerns over the battery life. Since more information is contained in Engineering Unit payloads, additional payloads are required to be transmitted, which puts more demand on the battery. The effects of additional payloads on battery life can be modeled in the Volley Boast Customer Portal in the Tools section.

Conclusion

With Engineering Unit Reporting, the VoBo allows users to skip the complexity of transforming data and go straight to meaningful, usable insights. Whatever analog sensor you are monitoring, the VoBo’s ability to report in engineering units saves time, reduces errors, and streamlines the process of delivering meaningful data.

For more information, visit the VoBo endpoints page or contact info@volleyboast.com.