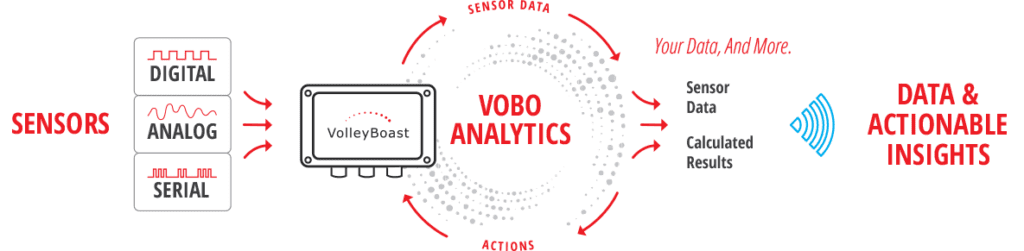

VoBoAnalytics is a licensed feature that enhances the functionality of VoBo devices by enabling on-board data analysis and action based on predefined conditions or algorithms. It runs customer-defined algorithms on sensor data, bringing computational power to the data source.

What is VoBoAnalytics

When we think of analytics, we typically think of statistics, such as the number of times something occurs within a measurement cycle. VoBoAnalytics takes this further by performing calculations on data that can be reported and used to trigger a change in the way the VoBo performs.

VoBoAnalytics is additional firmware code for the VoBo that can run algorithms to process data from a single channel, multiple channels, or even Modbus® RTU data. The results can be reported alongside, or in place of, the original data. This can be configured based on your needs.

VoBoAnalytics can also trigger actions within the VoBo based on the calculated results. Actions include transmitting data, changing the VoBo’s configuration parameters, writing to a Modbus® register, or dynamically adjusting the measurement intervals. This provides for customization.

How VoBoAnalytics Works with VoBo

VoBoAnalytics requires a one-time license fee. The firmware plugin is installed before your VoBo ships. Once the VoBo with VoBoAnalytics is added to your LoRaWAN® network, the analytics processing is integrated into the VoBo measurement cycle. Here’s a look at how it works:

1. Data Input

The VoBo collects data from the connected sensors or devices, including analog, digital, and Modbus® register data

2. Analytics Processing

The VoBoAnalytics plugin processes this data on the VoBo, using user-defined algorithms. These functions can calculate statistics, determine rates of change, and analyze data from multiple channels. Modbus® register data can be decoded and analyzed, including FP32 data.

3. Triggering Action

Based on the analysis, VoBoAnalytics can trigger actions such as transmitting alerts when thresholds are met, adjusting configuration parameters, or writing to Modbus® registers.

4. Data Transmission

The VoBo can transmit the raw sensor data, the calculated results, or both, depending on the user’s needs.

Common and Custom Analytics Functions

VoBo Analytics can apply commonly used analytical functions to collected data or apply a custom algorithm. We can develop custom functions tailored to your specific needs, or add your proprietary analytics to the VoBo before shipping. Your proprietary analytics will remain private.

VoBo analytics enables a variety of specific data analysis at the device level, including:

- Compute statistics such as minimum, maximum, average, mode, and standard deviation of data channels.

- Reporting analytical results only or along with the raw data.

- Transmit an alert when a measured or calculated value meets a certain threshold.

- Calculate the rate of increase or decrease in data channels.

- Perform calculations that compare or combine multiple input channels.

- Collecting data at high frequency, calculating results, and reporting at a lower frequency.

- Triggering data transmission based on specific conditions.

- Converting pulse counts to measured quantities and reporting calculated totals.

- Dynamically adjusting VoBo configuration parameters based on calculation results, such as increasing measurement frequency when a threshold is met.

Benefits of VoBoAnalytics

VoBoAnalytics offers several key advantages that differentiate it within the Industrial Internet of Things (IIoT) space. Here are just a few of the many benefits of using VoBoAnalytics with your LoRaWAN® platform.

Edge Processing

VoBoAnalytics performs data analysis and computations at the very edge, on board the VoBo itself. This can reduce the amount of data transmitted, reducing the potential for packet collisions and lost data, while enabling quicker decision-making and automated actions.

Flexibility and Customization

Users can define custom algorithms for data analysis or apply common analytics functions. This adaptability means VoBoAnalytics can be tailored to meet a wide range of industrial application needs.

Actionable Insights and Automation

VoBoAnalytics goes beyond just data reporting by enabling the VoBo to initiate actions based on calculated results. For example, it can be programmed to increase the frequency of sensor readings when a certain threshold is exceeded or to send alerts when specific conditions are met. This ability to trigger responses based on data analysis leads to greater automation and control in IIoT systems. This can improve operational efficiency and decision-making.

Optimized Data Handling

VoBoAnalytics streamlines data management and lowers the bandwidth used by collecting data at a high frequency, calculating the results, and then reporting those results at a lower frequency, reducing network traffic and post-processing requirements.

VoBoAnalytics Use Cases

Many use cases highlight the power of VoBoAnalytics. Here are a few use cases that show how VoBoAnalytics extends the power of data analysis to the edge, facilitating quicker responses to critical events and optimizing operations.

1. Condition Monitoring and Predictive Maintenance

Monitoring equipment parameters – By analyzing data such as temperature, pressure, vibration, or flow rates at the edge, potential equipment malfunctions can be identified and acted upon proactively.

Predicting equipment failure – Applying analytics algorithms to sensor data allows for predicting when equipment might fail, enabling scheduled maintenance instead of reactive repairs.

Optimizing operational efficiency – By monitoring and analyzing equipment performance at the edge, manufacturers can identify areas for improvement and streamline their production processes.

2. Process Optimization and Quality Control

Better process control – Adjusting processes based on analytical results derived from sensor data at the edge. For example, increasing the measurement frequency when a certain threshold is exceeded.

Improving process quality – Collecting and analyzing data from various points in a process helps identify variations, supporting quicker adjustments to ensure optimal quality.

Reducing waste and improving resource management – By monitoring and analyzing resource consumption, businesses can identify waste and implement strategies to reduce it.

3. Safety and Compliance

Monitoring hazardous environments – VoBos can be used to collect data in dangerous locations, improving safety by remotely monitoring conditions and triggering alerts if necessary.

Ensuring regulatory compliance – Near real-time data collection and analysis helps in meeting and demonstrating adherence to regulatory standards.

4. Environmental and Structural Monitoring

Remote monitoring of environmental parameters – Tracking water levels, concentrations, temperature, or other environmental factors in near real-time.

Geotechnical and structural health monitoring – Monitoring slope stability, landslide risk, and structural integrity in civil engineering projects.

Conclusion

VoBoAnalytics provides a powerful solution for transforming raw sensor data into valuable insights and enabling automated control within IIoT systems by offering edge processing, flexibility, actionability, and smart monitoring capabilities.

This allows users to gain insights from sensor data directly at the collection point, which can improve the data integrity, help reduce the amount of raw data sent to a central server, and improve bandwidth usage and response times.

VoBoAnalytics differentiates the VoBo from your typical LoRaWAN® endpoint. Collect data, analyze it in real time, and gain actionable insights all at the very edge. VoBo is the clear choice when you want more than monitoring from your IIoT network.