Background: Industrial Steam Systems

The use of steam is critical to many processes found in an industrial process plant. Steam is widely used throughout industrial processes, providing cost-effective energy for the plant. The steam system can account for 30-50% of energy consumption at an industrial plant so optimization of the system can account for significant energy savings. For an optimal steam system, it is important that the steam is of the correct quality, quantity, and pressure at the point of use. The quality of the steam is measured by the dryness of the steam, the higher the dryness of the steam, the more available energy. A component utilized throughout the system to manage the quality of the steam is the steam trap. A typical industrial process steam system can have thousands of steam traps. A steam trap releases condensate and incondensable gases while not allowing the escape of live steam, improving the quality and effectiveness of the steam system.

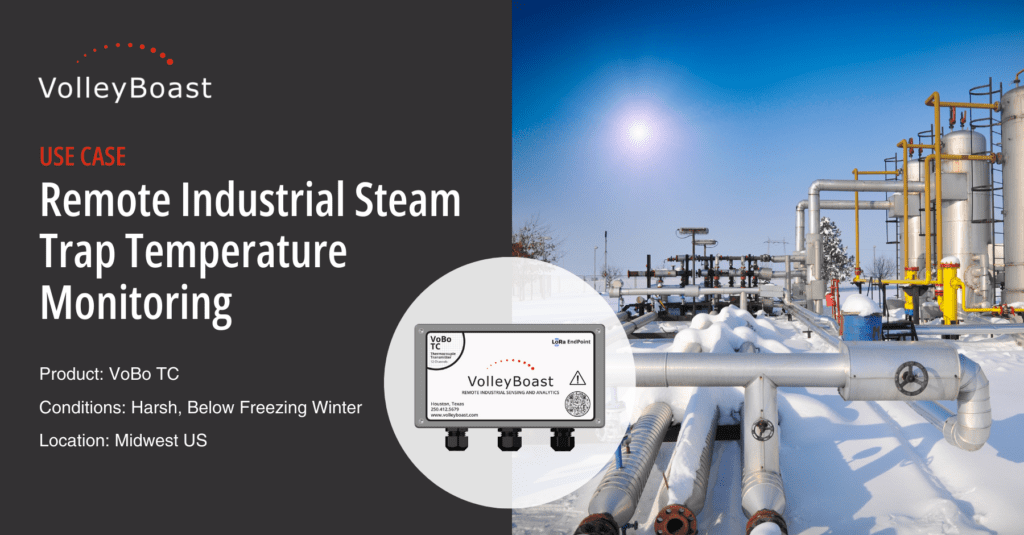

Challenge: How to Monitor Steam Trap Temperatures

Industrial plants in any geography which during the winter months see temperatures below freezing, have increased potential for steam trap failure. Failures can be caused by, among other things, condensed water freezing in the steam trap, reducing its effectiveness, or rendering it inoperable. Frozen condensation in steam traps reduces the quality of the steam and effectiveness of the steam system, creating inefficiencies, higher operating costs, and problems in production. As with any piece of equipment, for proper operation, steam traps must be monitored and maintained. In this case, the customer’s plant is in the US Midwest where extreme low temperatures are routinely seen in the winter months. Monitoring the operation of thousands of steam traps had been a manual process which involves a physical inspection by a technician. The required inspections during the winter season are critical due to the increased likelihood of a frozen or inoperable steam trap. Inspections are physically demanding for personnel, have exposure risks, and can be a reaction to a problem condition.

Solution: Using the VoBo TC to Monitor Steam Trap Temperatures

To minimize the manual inspections, and manage steam trap maintenance and repair more efficiently, the customer wanted the temperature data of thousands of steam traps available on their LoRaWAN network. Thermocouple sensors were selected for this application due to their robust options and low cost, important considerations on a large-scale deployment. Each thermocouple monitors the temperature of a steam trap outlet piping. The data allows the customer to know if the steam trap has frozen and requires maintenance. The VoBo TC was selected to bring the thermocouple data into the customers’ network. The VoBo TC is a bridge device, deployed to collect sensor data from up to 12 thermocouples per installation, and transmit that data to a LoRaWAN network.

Results: Reduced Risk and Minimize Manual Labor

Having steam trap temperature data minimizes personnel dependent inspection processes and identifies problem areas faster. Corrective actions can be more effective and less disruptive to the process. Personnel exposure to adverse weather conditions is reduced, the steam quality and process efficiencies are improved, saving operating cost and reducing risk. The deployment includes thousands of thermocouples and hundreds of VoBo TCs, the ability to monitor 12 thermocouples per VoBo TC installation is a significant deployment cost savings. The LoRaWAN network’s inherent ability to scale allows hundreds of endpoints to be easily added to the network by bulk loading the VoBo TC device data into the LoRaWAN network server.