When we started VolleyBoast, we anticipated the biggest opportunity for LoRaWAN solutions was to provide a straightforward solution for acquiring data from points that were too expensive to run power and communications cables. Cost-effective access to data permits more efficient operations. Our initial target markets were new facilities or data acquisition from new measurement points at existing facilities.

We continue to see tremendous opportunity for such greenfield applications. However, opportunities to get stranded data off legacy equipment and instead use LoRaWAN for brownfield applications is potentially as good a use case as is that for greenfield solutions.

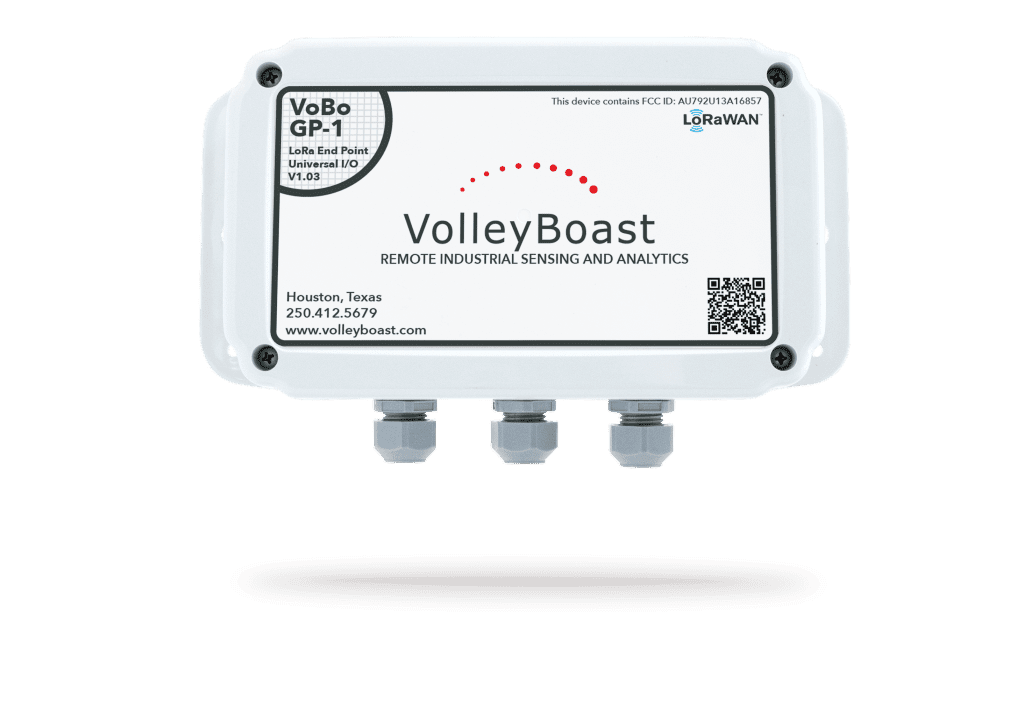

Following are three such brownfield applications for VolleyBoast’s VoBo:

- Equipment that communicates via Modbus but does not have a good way to get that data to a control room

Several of our clients have come to us wondering if the VoBo can collect data from legacy controllers/transmitters. Their facilities might have grid powered controllers/transmitters installed that are perfectly accurate but require an operator to physically observe the device to obtain readings. These clients are now using the VoBo to wirelessly transmit the data to their control rooms. Specific examples are: legacy GenSets and compressor stations with local control systems, flow controllers, combustion analyzers, heat trace controllers, and alkalinity monitors. Most legacy controllers have a combination of digital alarm outputs, Modbus RTU outputs, and perhaps some analog outputs. One VoBo can easily be configured to pick up this stranded data and send it wirelessly to a control room. The VoBo, being battery powered, requires minimal installation cost and, because it is not supplying power to the controller, the battery life may well be over a decade. - Safety equipment that is not otherwise connected

Fire alarms, eye wash stations, emergency showers, and a host of other equipment often do a great job assisting with problems in the immediate area. However, such equipment has historically been deployed without the ability to alert operators/management of a situation requiring action or monitoring so critical assistance can be appropriately deployed. Retrofitting this equipment with a VoBo can bring the equipment online in a matter of minutes and greatly reduce response time to any incident that may occur. - Monitoring effluent and noxious/toxic emissions

Older equipment tends to create the most problems with pollution and discharges that negatively impact the environment. A few strategically placed VoBos can bring such equipment into environmental regulatory compliance, benefitting not only the operator but the surrounding community as well.

The VoBo fits right in with the latest technology and wireless solutions. However, it also presents an excellent opportunity to extend the useful life of many varying types of equipment and systems. Please reach out to us if you have any thoughts and/or questions as to how such solutions might work in your plants and facilities.